Sheet Piling

Composite piles include round/octagonal pipes and sheet piles. Round/octagonal pipes general diameters are from 8" to 14", the length can be 4ft~20ft even 30ft.There are three types of composite sheet piles, light piles, heavy duty sheet piles and super heavy duty piles. The length, width, wall thickness and materials will decide the strength of sheet pile. Common shapes of sheet piles are Z-pile and box pile.

| NO. | Item | Technical Data |

| 1 | Pile Shape | Z-Profile |

| 2 | Section modulus(Z) | 698cm3/m |

| 3 | Moment of Inertia | 37.15 in4/ft |

| 4 | Section Modulus | 10.25 in3/ft |

| 5 | Working Stress | 12,500 psi |

| 6 | Allowable Moment | 48.19KN/m |

| 7 | Cross-Sectional Area | 3.98 in2/ft |

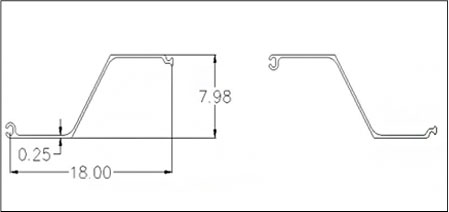

| 8 | Width of Sheeting Section | 18.00" |

| 9 | Section Depth | 7.98" |

| 10 | Thickness | 0.25" |

| 11 | Weight | 4.49 lbs/ft |

The drawing of Z-pile and box pile:

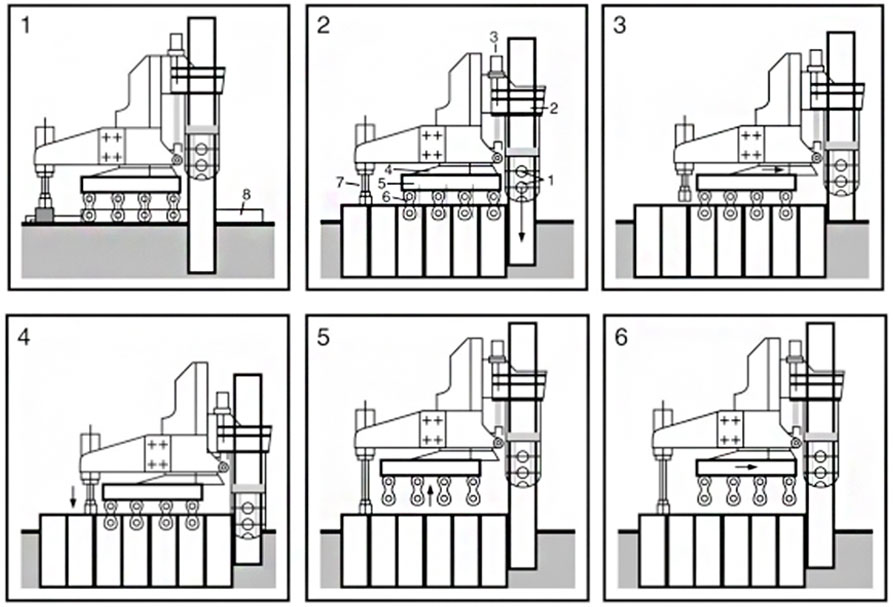

MACHINE OPERATION SINGLE PILE PRESS:

- Setting of press and reaction table No.8. For the first pile supplementary weight can be up on to the machine.

- In normal working, reaction force is taken from the already pressed piles.

- Support No.7 is lifted and press head moves forward.

- New pile is pressed to give support.

- Engine, sitting on pile and support No.7, lifts the clamp unit No.5.

- Clamp unit moves forward to fix to installed piles again.